PRODUCTS

CATEGORIES

CONTACT US

SPD-605 pull-out welding boom

Product Description

Introduction:

1. Application scenarios

Xutai SPD-605 welding boom as a special equipment for auxiliary welding, can be widely used in shipyards, machinery manufacturing, agricultural machinery manufacturing, steel structure and other industries.

2. Pull arm

The forearm can be pulled, and the arm length can be customized according to the actual needs. In order to accommodate different welding positions and working Spaces, it is easy to cover each welding point.

3. Advantages

The space arm is compact and easy to stretch. The box structure design reduces the time required for inspection and cleaning work, and also reduces the frequency of welding material replacement. The advanced design greatly enhances the stability of the space arm.

4.Length

The length of the welding boom is generally 2-10 meters, which can be customized according to the actual welding needs of the enterprise.

5.Color

The main color of the wire feeder arm is yellow, orange red, green, etc., and the color can be customized according to requirements.

Parametric graph:

Parameter Table:

Customer Case Diagram:

Q&A:

1. Q: What are the driving forms of the welding boom? How well do they match?

A: At present, the driving forms of XUtai welding boom include manual hydraulic type, spring self-balancing type, electric remote control type, pull type and other driving forms. The adaptability of the equipment is very high, which can not only customize the arm length and drive form according to the actual welding needs, but also effectively reduce the frequent movement and adjustment of the workpiece in the welding process, so as to better improve the welding efficiency.

2. Q: Is the installation and operation of Xutai welding boom convenient? Will it take up a lot of space?

A: The overall structure of the welding boom is compact, and no large area of fixed site is required for installation. The modular assembly method is adopted, which is easy to use and easy to operate. At the same time, the multi-stage boom design can be extended and folded according to the need to adapt to different welding positions and working Spaces, which can greatly save the space of the welding workshop.

3. Q: Can welding efficiency be improved by using the welding boom?

A: The welding boom can significantly improve the welding efficiency. On the one hand, it can stably hang the welding gun at the appropriate operating height, reduce the physical consumption of workers holding the welding gun, reduce the labor intensity and improve the welding efficiency. On the other hand, it can flexibly adjust the welding Angle, avoid rework caused by limited operation posture, accelerate the progress of welding operation as a whole, and ensure the welding quality.

4. Q: How durable is the welding boom? Does daily maintenance take a lot of effort?

A: The products are made of high-quality materials, with good wear resistance and deformation resistance, and can better adapt to the high-intensity working environment of the workshop. Daily maintenance is also relatively simple, only need to regularly check the fastening situation of the connection part, wipe the surface dust and welding slag, etc., without complex maintenance process and high maintenance costs, reduce costs and improve welding quality.

5. Q: Does the use of welding boom help to improve the welding working environment?

A: Welding boom can effectively improve the welding environment. It can better collect cables, avoid tripping risks caused by messy stacking of cables, and effectively improve the welding efficiency. In addition, the high-efficiency dust collection device equipped with it can reduce the disordered diffusion of welding smoke and harmful substances, make the welding working environment cleaner and safer, and improve the safety of welding workers.

6. Q: What about after-sales service for customers and machines?

A: We provide a lifetime free online technical support service. When there is a problem with the equipment, we will solve it for you as soon as possible.

7. Q: How many years has the company been working in this field?

A: We have been working in this field for over 17 years. We have rich experience in the design and manufacture of machinery. We continue to improve according to the feedback from the domestic and foreign markets, and currently we have a full range of multiple space arm products.

Company Profile

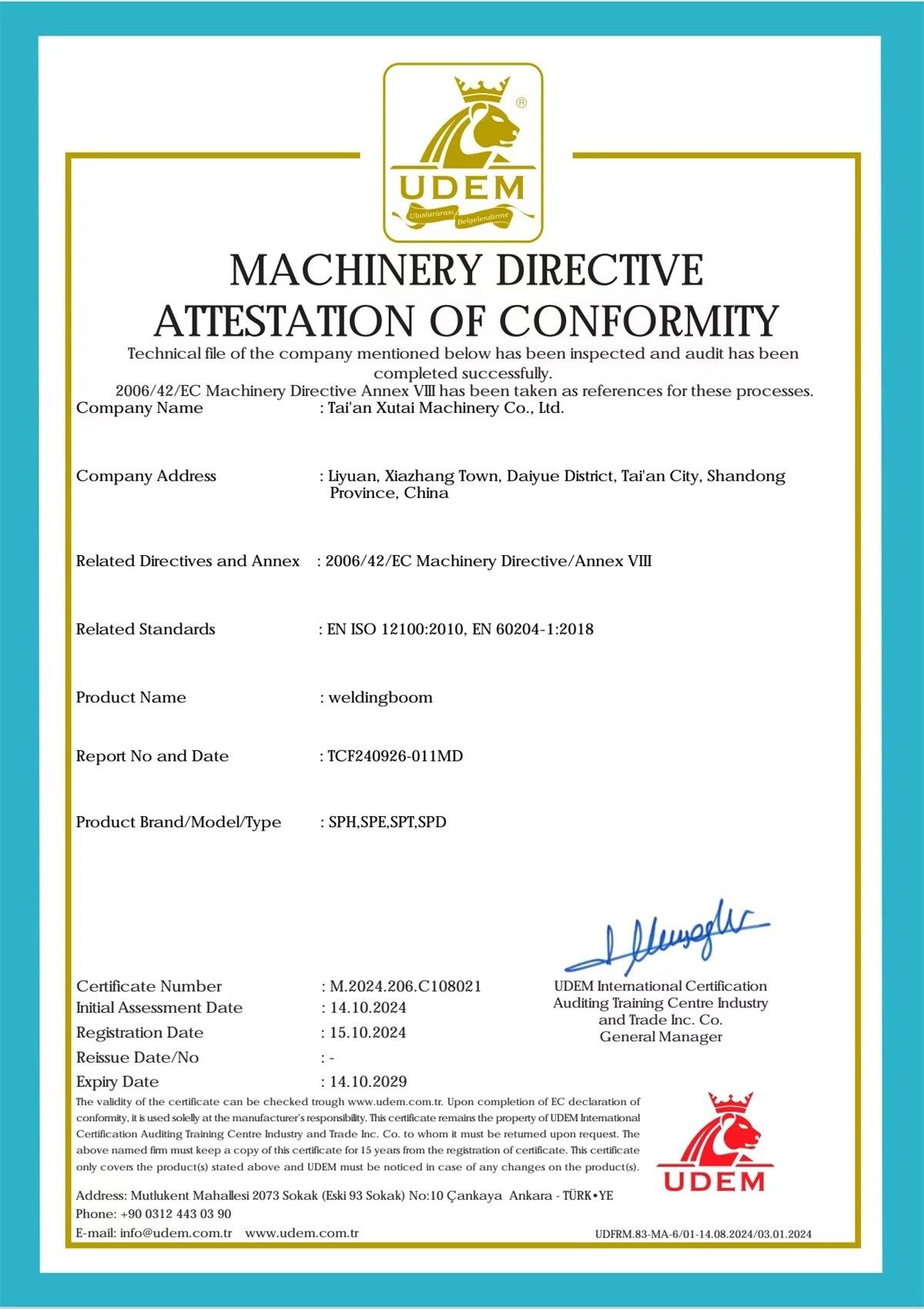

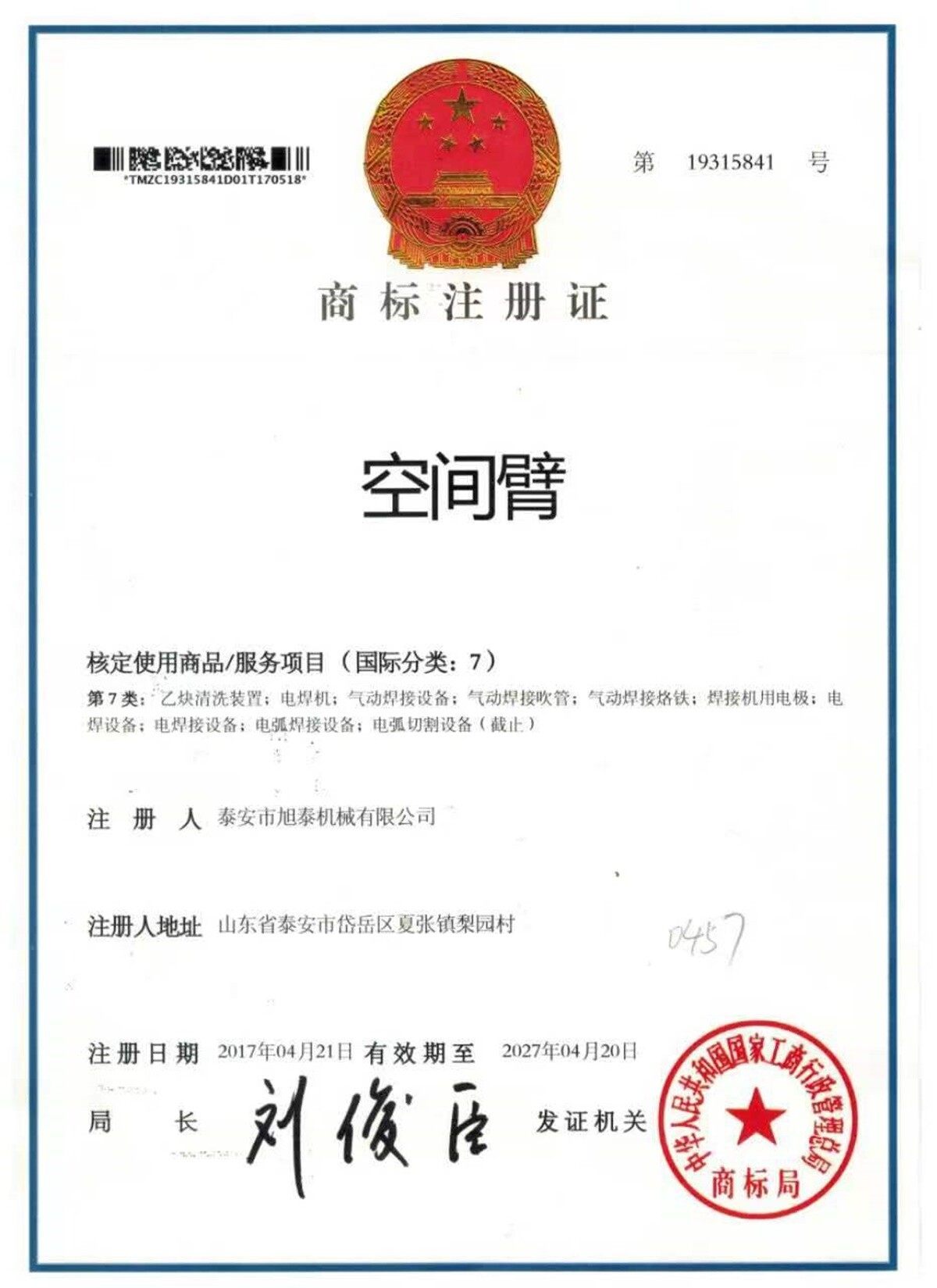

Our company is located in Tai 'an, Shandong Province, China, is a mechanical equipment manufacturer with a history of 10 years. Our company is a production enterprise integrating scientific research and production, successfully developed 16 patents of welding arm with intellectual property patents, more than 10 copyrighted products, our company has independent product trademarks, and passed ISO and CE certification.

We continue to improve according to the feedback of domestic and foreign markets, and now have a full range of multi-model welding boom products. The products are widely used by many countries and well-known enterprises, which greatly improves the on-site management level and product quality of customer enterprises.

Our Certificate

Packaging and Transportation

Related products

Message

CONTACT US