PRODUCTS

CATEGORIES

CONTACT US

Pull welding boom

Product Description

Optimized & Detailed Welding Solution Advantages

1、Zero Welding Dead Zones

Enjoy unobstructed access to every welding angle and workpiece position, eliminating frustrating limitations that force repositioning or compromise weld quality. Whether tackling complex joints, large assemblies, or hard-to-reach areas, this solution ensures consistent, precise welds without any coverage gaps.

2、No More Dragging Heavy Welders

Say goodbye to the physical strain of maneuvering bulky welding equipment across the shop floor. Our system keeps your welder securely positioned in an optimal, fixed location—freeing you from unnecessary lifting, pulling, or repositioning that wastes energy and slows down workflows.

3、Tangled & Cut Cables Become a Thing of the Past

Bid farewell to the headaches of tangled, kinked, or accidentally severed welding cables. With a streamlined, organized cable management design, wires are routed neatly and protected from damage caused by foot traffic, heavy machinery, or sharp workpiece edges. This not only saves time on untangling but also extends cable lifespan and reduces costly replacements.

4、A Clean, Clutter-Free Shop Floor

Eliminate the chaos of scattered equipment, loose cables, and misplaced tools that plague traditional welding setups. Our solution promotes a tidy, streamlined workspace where every component has a dedicated place—transforming cluttered welding areas into a clean, professional environment that’s easy to navigate and maintain.

5、Dramatically Increased Workplace Safety

Safety is engineered into every detail. By removing tripping hazards from loose cables and floor clutter, we minimize the risk of slips, falls, and equipment-related accidents. The fixed welder setup also reduces the chance of operator fatigue or strain from moving heavy gear, while protected cables eliminate electrical hazards caused by fraying or cuts. The result? A safer work environment that protects your team and reduces downtime from injuries.

6、Boosted Productivity Across the Board

Cut down on non-value-added tasks to maximize time spent on core welding work. No more pausing to untangle cables, reposition equipment, or clean up clutter—operators can focus solely on welding, which directly increases output and project turnaround speed. A smoother workflow also reduces downtime between welds, letting you take on more jobs and meet tight deadlines with ease.

7、Engineered to Perform, Built to Last

Crafted with rugged, high-quality materials and precision engineering, this solution is designed to stand up to the rigors of daily industrial use. It delivers consistent, reliable performance—even in demanding welding environments—while its durable construction minimizes maintenance needs and ensures long-term value, avoiding the hassle and cost of frequent repairs or replacements.

8、Reduced Time Spent on Non-Welding Tasks

Slash the hours wasted on setup, equipment adjustments, cable management, and workspace cleanup. Every feature is optimized to minimize these administrative and logistical chores, letting your team spend more time doing what they do best: welding with speed and precision.

9、A Clean, Organized Welding Cell

Achieve a highly efficient, well-structured welding zone where tools, cables, and workpieces are perfectly organized. This level of order not only speeds up workflow but also makes it easier to maintain quality control, track materials, and keep the workspace compliant with safety standards.

10、Eliminates Tripping Hazards & Shop Floor Clutter

By consolidating equipment and routing cables securely, we eradicate the primary causes of shop floor accidents. Loose wires, scattered gear, and misplaced materials are no longer a threat—creating a clear, hazard-free path for operators to move around safely, even in busy production environments.

11、Increased Operator Safety, Motivation, and Productivity

A safe, organized workspace doesn’t just protect your team—it boosts morale and motivation. When operators don’t have to worry about tripping hazards or physical strain, they can focus on their work with greater confidence and efficiency. The result is a more engaged team that delivers higher-quality welds, faster output, and a more positive work atmosphere overall.

Company Profile

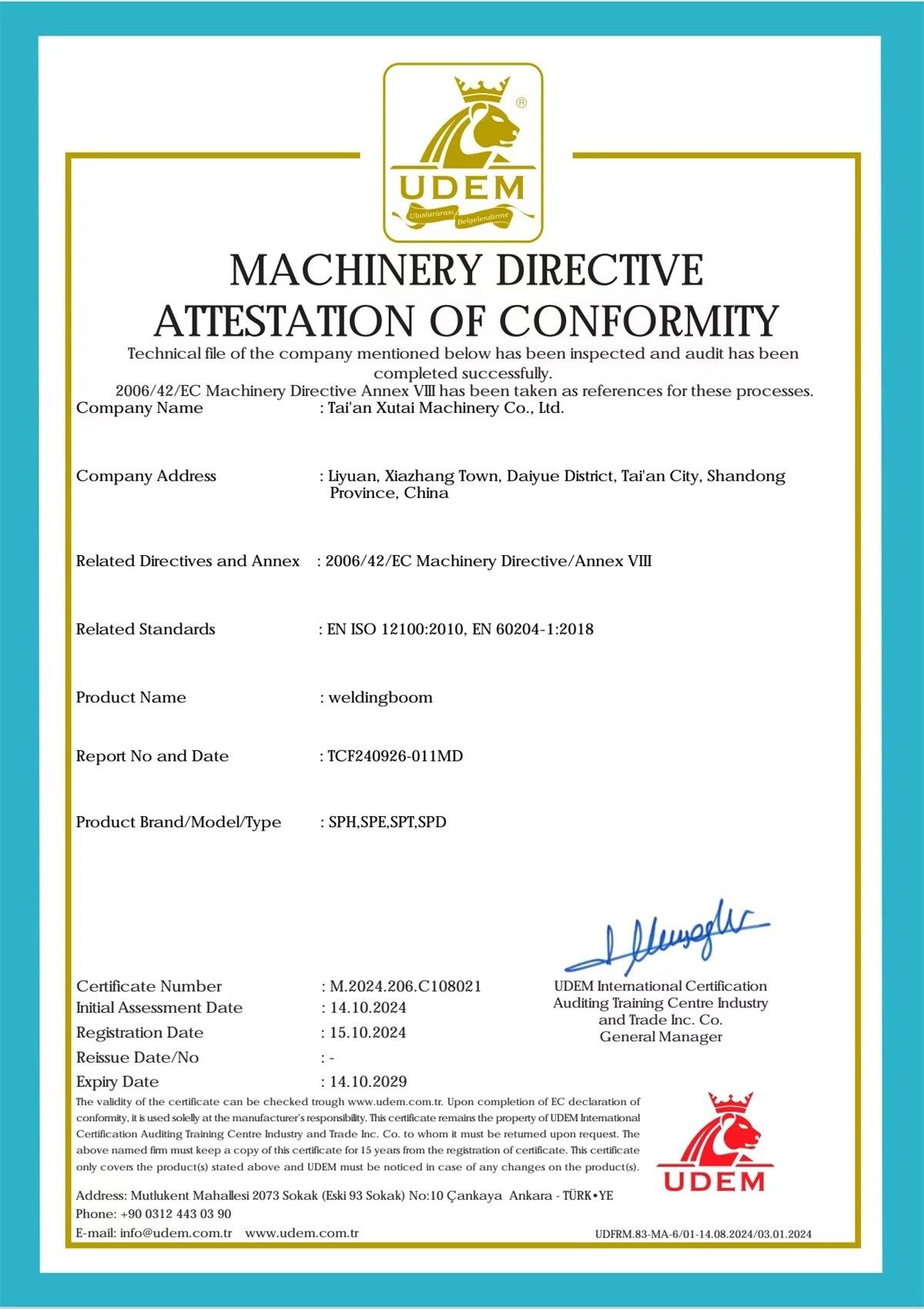

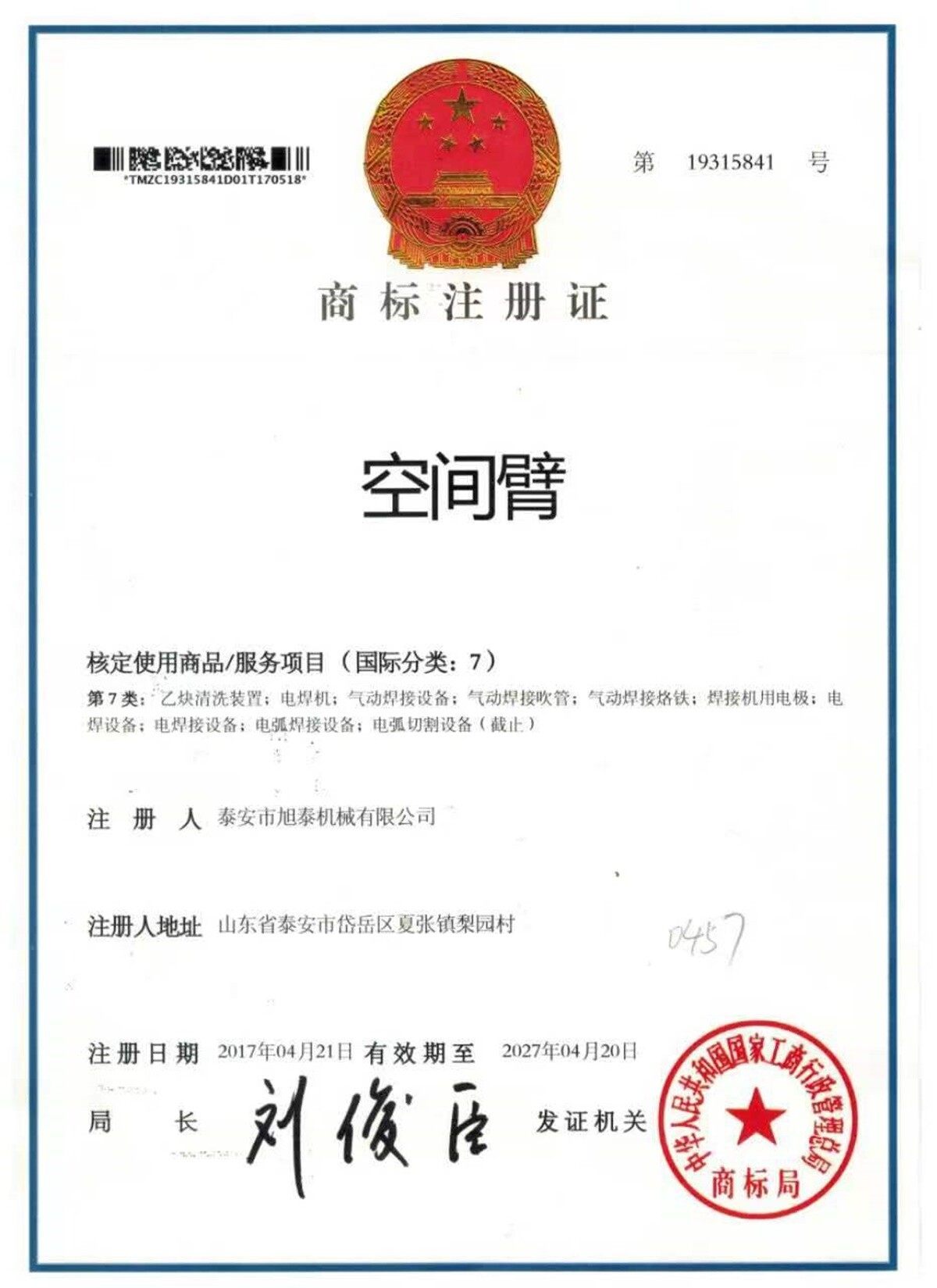

Our company is located in Tai 'an, Shandong Province, China, is a mechanical equipment manufacturer with a history of 10 years. Our company is a production enterprise integrating scientific research and production, successfully developed 16 patents of welding arm with intellectual property patents, more than 10 copyrighted products, our company has independent product trademarks, and passed ISO and CE certification.

We continue to improve according to the feedback of domestic and foreign markets, and now have a full range of multi-model welding boom products. The products are widely used by many countries and well-known enterprises, which greatly improves the on-site management level and product quality of customer enterprises.

Our Certificate

Packaging and Transportation

Related products

Message

CONTACT US